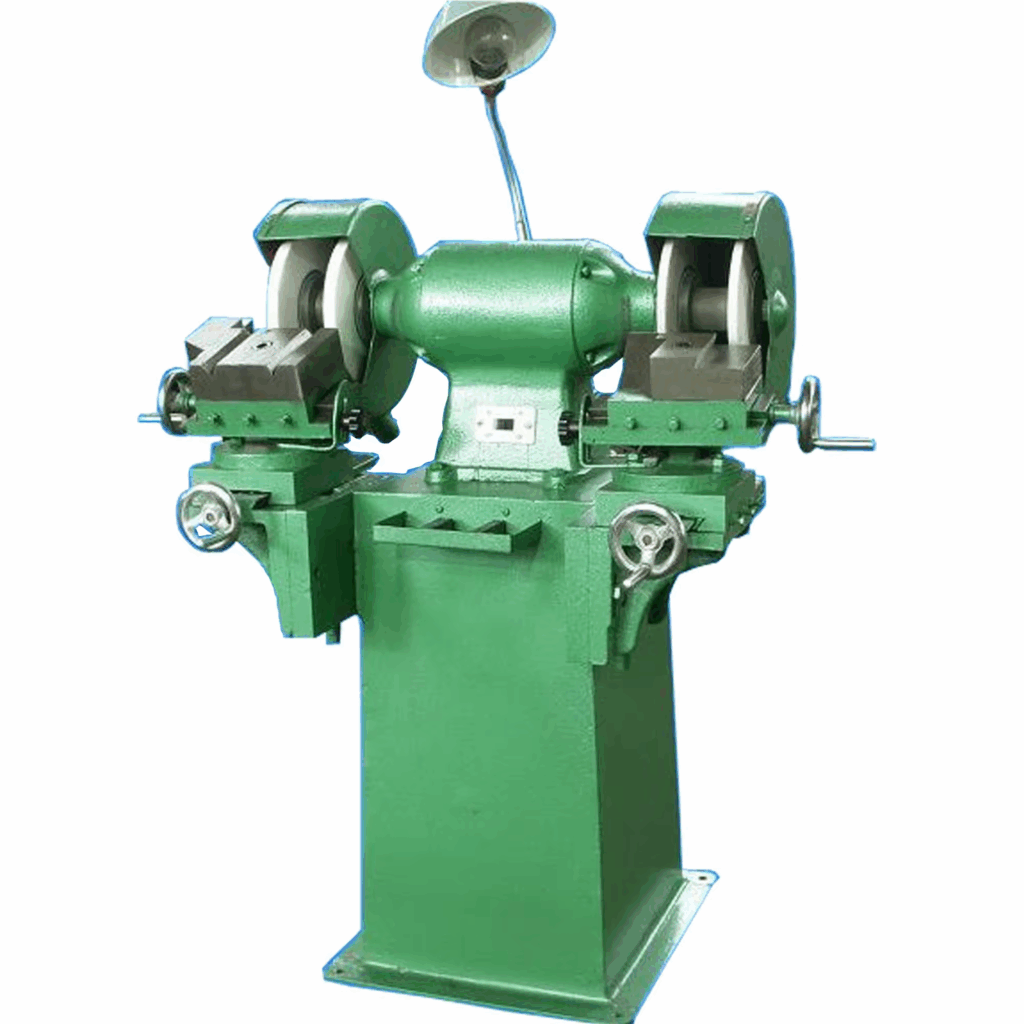

The Nail Cutter Grinder is an essential auxiliary machine used in nail production lines to maintain the precision and efficiency of cutting tools and molds. Over time, the blades and cutting surfaces in nail making machines can become dull, uneven, or damaged, which may lead to inaccurate nail lengths, rough edges, or increased waste. The Nail Cutter Grinder ensures that cutting tools are sharpened and restored, maintaining consistent nail quality and extending the life of the tools.

🔹 Key Features

- Precision sharpening: Restores the sharpness of cutting blades used in nail making machines.

- Maintains uniform nail length: Ensures every nail produced is accurate in size.

- Improves nail quality: Reduces burrs, rough edges, or deformed tips.

- Extends tool life: Properly maintained blades and cutters last longer, reducing replacement costs.

- Adjustable for different tools: Can handle various cutter shapes and sizes used in both Z94 and high-speed machines.

🔹 Technical Details (Typical)

- Power: 0.5–2 kW, depending on size and model

- Grinding Speed: Adjustable for precision sharpening

- Construction: Heavy-duty steel frame with grinding wheel or belt system

- Operation: Standalone machine, sometimes used inline for high-volume factories

🔹 Applications

✅ Sharpening cutting tools for traditional Z94 machines

✅ Maintaining rotary or high-speed nail machine blades

✅ Ensuring consistent nail length and head shape

✅ Reducing production defects and material waste

🔹 Advantages

- Ensures high-quality nails with precise length and smooth surfaces

- Reduces downtime by preventing tool failures during production

- Saves costs on frequent replacement of worn blades

- Supports continuous production in medium to large-scale factories